Martindale vs. Wyzenbeek: Which Abrasion Test Should You Use for Commercial Furniture Materials?

Wondering whether Martindale or Wyzenbeek is the right abrasion test for your upholstery material? This guide explains the key differences and how to choose the right standard for your commercial furniture projects.

Introduction: Abrasion Resistance Matters in Commercial Spaces

When choosing materials for commercial furniture—such as office seating, hotel sofas, or public lounge areas—durability is one of the top priorities. High-traffic environments demand surfaces that can handle frequent use without losing their appearance or integrity.

That’s why many fabric and leather suppliers test their materials for abrasion resistance. And when it comes to abrasion testing, you’ll likely come across two names: Martindale and Wyzenbeek.

In this guide, we’ll walk you through both tests, explain how they differ, and help you understand which one suits your market best.

What Is the Martindale Abrasion Test?

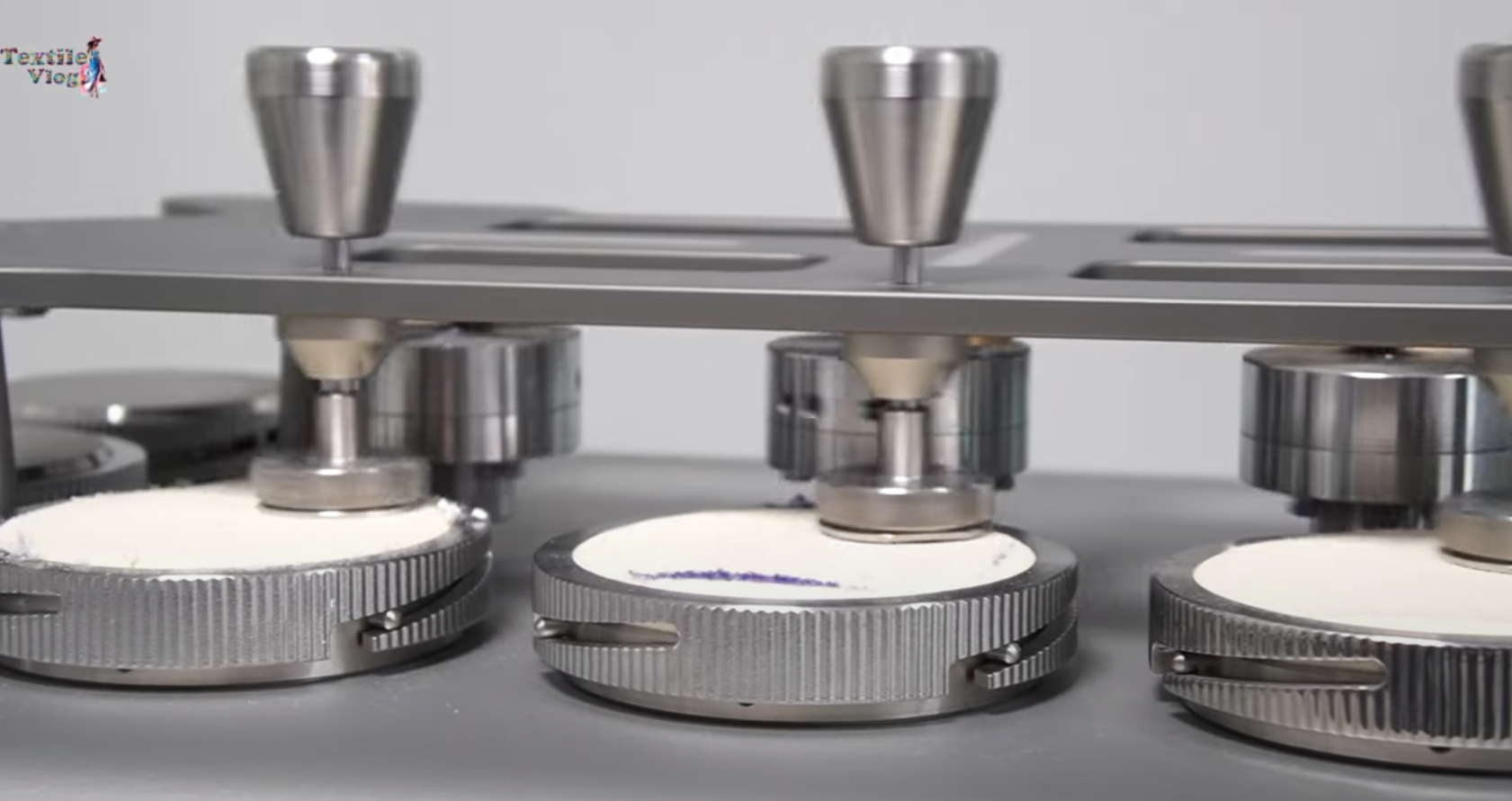

How the Martindale Test Works

The Martindale test is widely used across Europe and Asia. It evaluates how many cycles a material can endure when rubbed in a circular motion against a wool or abrasive fabric.

-

Follows ISO 12947

-

Measured in cycles

-

Simulates everyday wear caused by clothing and body contact

What the Results Mean

-

10,000 cycles: Decorative use

-

30,000–50,000 cycles: Light to moderate commercial use

-

100,000+ cycles: Suitable for high-traffic or contract-grade environments

Watch the Martindale test in action:

Martindale Abrasion Test – YouTube

What Is the Wyzenbeek Abrasion Test?

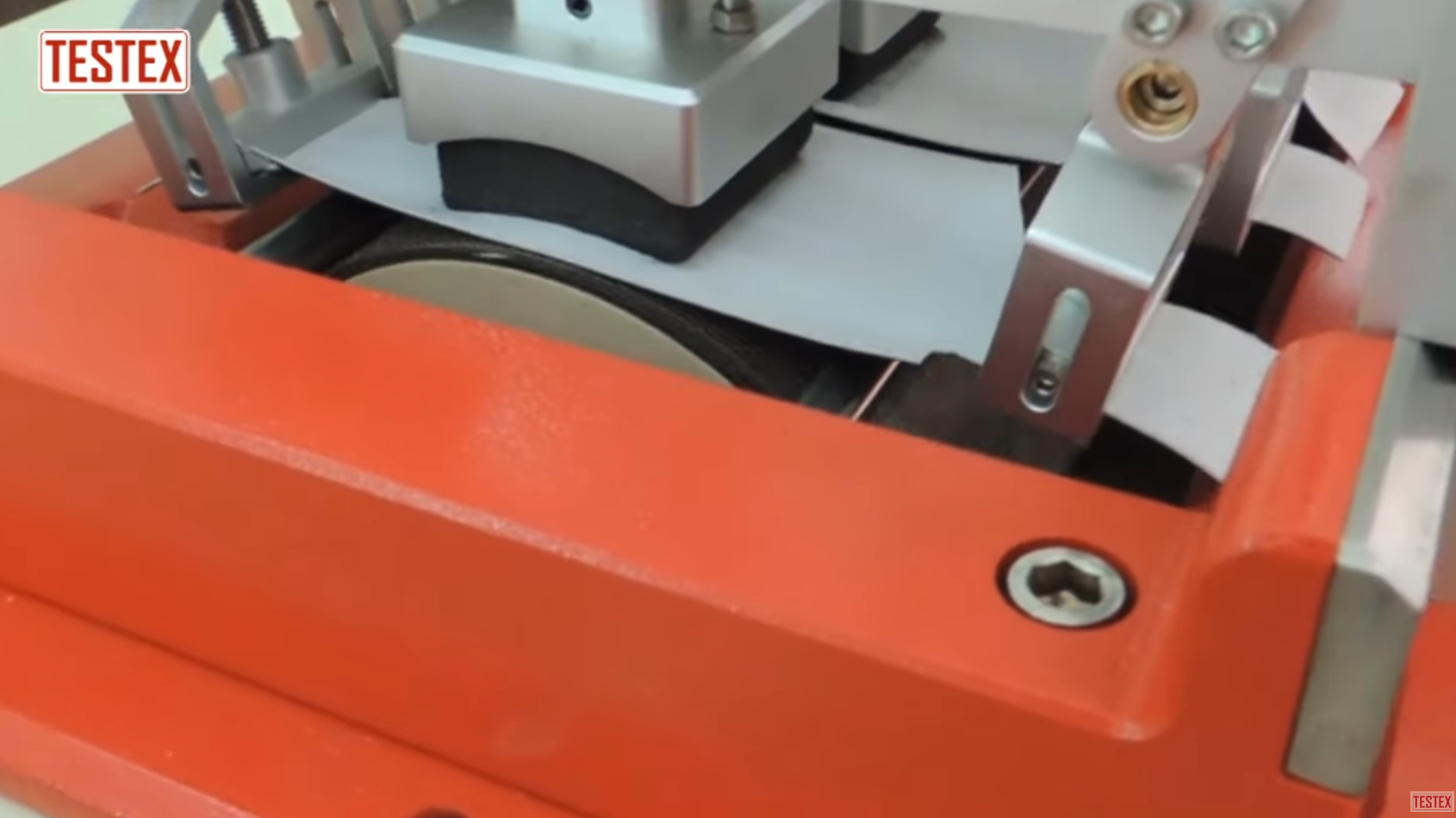

Testing Method and Motion

The Wyzenbeek test is the preferred method in North America, especially for contract and commercial furniture.

-

Follows ASTM D4157

-

Measured in double rubs (1 back-and-forth = 1 rub)

-

Simulates friction from sitting, sliding, or shifting

Understanding Double Rub Scores

-

15,000–30,000 double rubs: Residential or light commercial

-

50,000+ double rubs: High-traffic contract-grade

Watch the Wyzenbeek test in action:

Wyzenbeek Abrasion Test – YouTube

Martindale vs. Wyzenbeek: A Quick Comparison

| Feature | Martindale Test | Wyzenbeek Test |

|---|---|---|

| Motion | Circular (figure-8) | Linear (back-and-forth) |

| Abrasive material | Wool or sandpaper | Cotton duck or wire screen |

| Region | Europe, Asia | U.S., Canada |

| Unit of measure | Cycles | Double rubs |

| Common applications | Fashion textiles, soft seating | Office chairs, public seating |

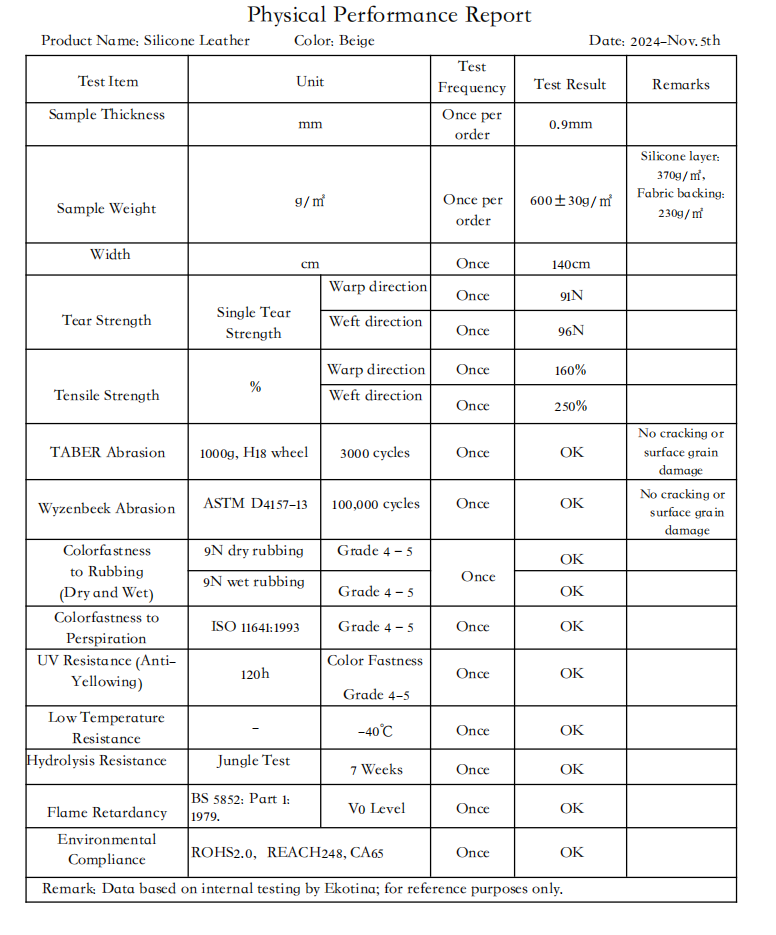

Does Ekotina Test Silicone Leather for These Standards?

Standard Testing Options

Yes.

At Ekotina, we understand the importance of verified performance, especially when our clients are building furniture for hotels, offices, airports, and other commercial environments.

We can test our silicone leather using either method depending on your region and project requirements.

Custom Testing Upon Request

We provide testing upon request before shipment, including:

-

Wyzenbeek: 100,000 double rubs

-

Martindale: Over 100,000 cycles

-

Additional tests: UV resistance, tear strength, Taber abrasion, flame retardancy, and more

Here’s an example from one of our internal test reports:

Note: Not all tests are run by default, but we’re happy to arrange testing based on your needs.

Conclusion: Which Test Should You Use?

If you're producing for the U.S. or Canada market, you'll likely need Wyzenbeek results.

If you're working with European or Asian clients, Martindale is more commonly requested.No matter which standard you follow, remember: it’s not just about the numbers—it’s about choosing the right material for your application.

Want Samples or Test Data?

Our silicone leather is engineered for performance, comfort, and sustainability.

Contact us to request samples or technical testing support for your next commercial furniture project.