what is silicone leather?

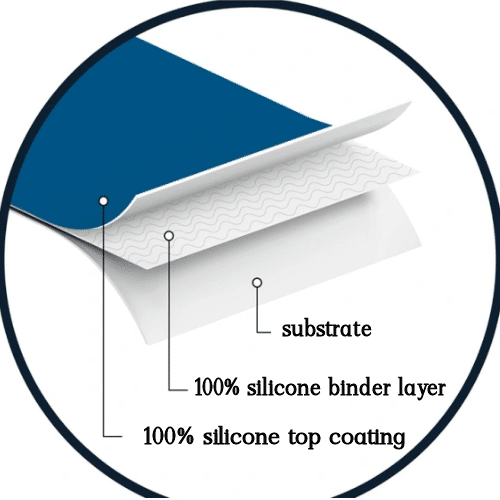

1. The composition of EkoTina silicone fabric:

EkoTina seamlessly blends the luxurious texture of leather with the exceptional performance of silicone. Its structure features a surface layer made entirely of 100% silicone, a middle laywith 100% silicone adhesive, and a variety of base fabrics, including polyester, spandex, and microfiber, providing a versatile foundation.

2. Introduction of silicone:

Silicone is a versatile polymer material known for its energy efficiency, resource conservation, safety, reliability, and high performance. It plays a role in our daily lives, protecting electronic devices from moisture and dust, enhancing kitchen tools with heat resistance and easy cleaning, and offering high-performance, hypoallergenic solutions in medical applications.

3. Silicone Characteristics:

Temperature Resistance: Silicone products boast exceptional thermal stability due to their molecular structure, making them resistant to extreme temperatures, both high and low, and suitable for a wide range of applications.

Weather Resistance: Silicone is highly durable in natural environments, resisting decomposition from ultraviolet light and ozone, which contributes to its long lifespan.

Low Surface Tension: With stain-resistant and hydrophobic properties, silicone surfaces repel water and maintain cleanliness with ease.

Non-Toxic and Odorless: Silicone is safe for use, being free from toxins and unpleasant odors, making it ideal for applications in healthcare, food, and everyday products.

4. EkoTina's silicone fabric performance

-

eco-friendly

-

high performance

-

low maintenance

-

Inherent stain resistance

-

UV stability : 1500+hours

-

Abrasion :

-

1-Wyzenbeek 200,000+ double rubs

2-Martindale 120, 000 cycles

-

Low-temperature flex resistance: IOS17694, -30℃ 200,000+

-

Salt spray resistance: ASTM D4329-05 (QUV) 1000+hours

-

Hydrolysis resistance: ASTM 3690-02, 14+weeks

-

Cold crak resistance: 5# rollers, CFFA-06

-

UV stability-ASTM D4329-05(QUV), 1500+hours

-

Colorfastness:

-

Light FAstness: AATCC16.3 200h, Grade 4.5,

-

Crocking: AATCC8, Wet& Dry, Class 5

-

Inherent flame resistance

CATB117-2013

ASTM E84(adhered)

FMVSS #302

IMO 2010 FTP Code(Part 8) by LR

NFPA 260 Class I

UFAC Class I

EN 1021 Part I and II